Robust API powering international logistics and stock management across the Coca-Cola distribution network

Fragmented inventory tracking across regions

Limited visibility of product movement between locations

Inconsistent data between manufacturing and distribution centers

Manual reconciliation processes causing delays

Coca-Cola was managing inventory across multiple regions with disconnected systems, leading to inefficiencies in their global supply chain.

The company needed a unified global inventory system that could track products across countries, optimize stock levels, and provide real-time visibility into the entire supply chain from production to retail.

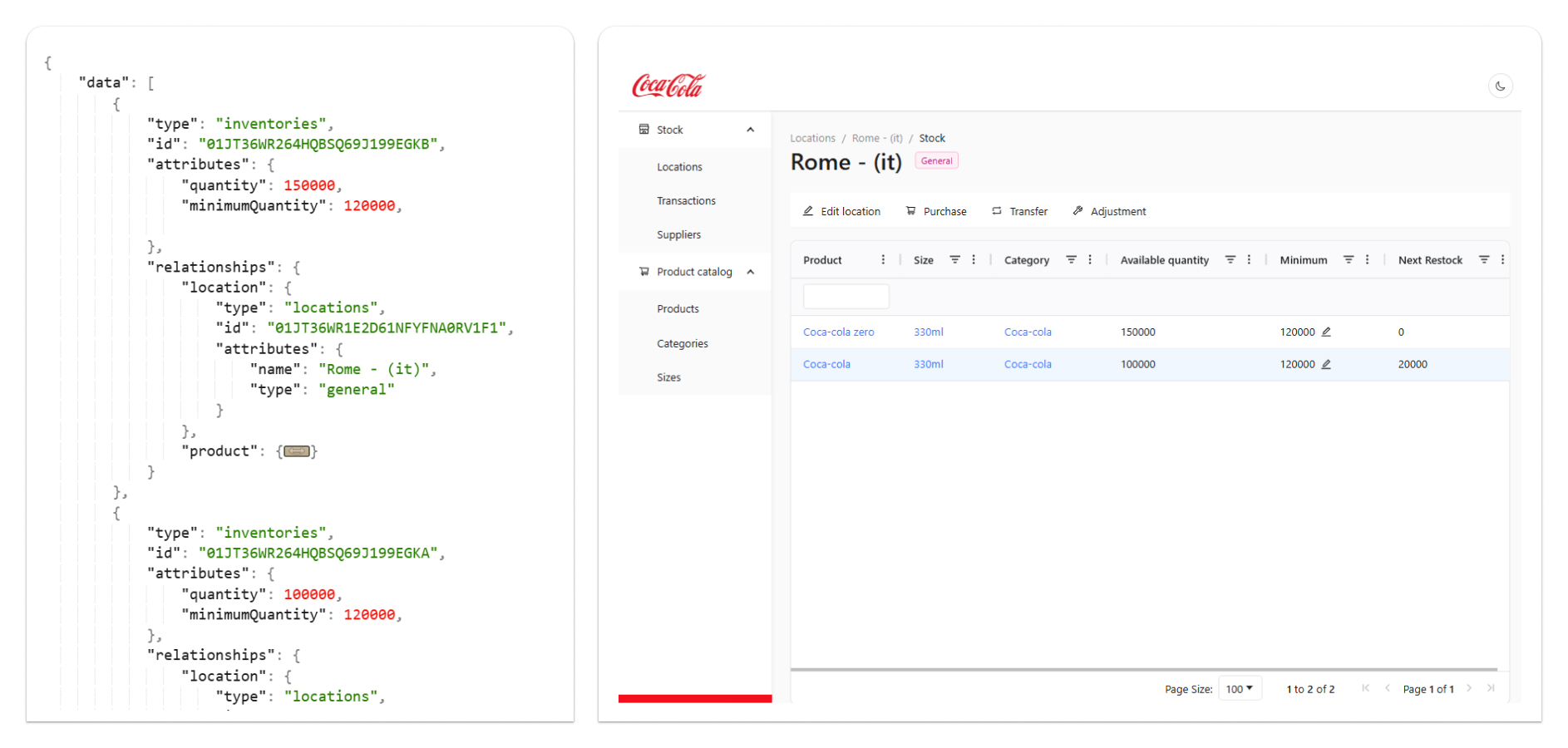

Hierarchical location management (Country/Region/City/Facility)

Product catalog with categories, sizes, and regional variants

Real-time stock level monitoring across all locations

Automated transfer management between facilities

Forecasting and demand planning integration

Comprehensive transaction history and audit trails

Multi-currency support for international operations

Role-based access control for regional teams

We developed a comprehensive API-driven inventory management system that connects manufacturing plants, distribution centers, and retail locations worldwide.

30% reduction in stockouts across distribution centers worldwide

18% decrease in overall inventory carrying costs

Real-time visibility into product movement across 200+ countries

Optimized shipping routes saving 12% in transportation costs

Reduced product waste by identifying slow-moving inventory before expiration

The global inventory management system has transformed how Coca-Cola tracks and manages product across their international supply chain.

The API-driven inventory system now forms the backbone of Coca-Cola's global logistics operations, enabling unprecedented efficiency in their supply chain and supporting continued international growth.